◊ Our Services ◊

… from the initial idea to the final product!

1. Sales / Customer Service

Whatever questions you might have regarding our products, production processes or the preparation of quotations, our highly experienced customer service team will be happy to assist you. All questions from both new and existing customers will be dealt with swiftly and competently before any concepts / ideas submitted to us are passed on to our team of graphic designers.

2. Graphics department

Every new product starts with an original idea or vision. Thus, whatever reference material you would like to or might be able to supply, e.g. photos, sketches or just a rough idea, our expert team of graphic designers will help turn this idea into the perfect design. Working closely with all our customers at every stage of this process, the design will undergo continuous improvements until it meets your vision and a final design can be approved. Based on this final design, the tools will be produced by our in-house specialists.

2. Graphics department

Every new product starts with an original idea or vision. Thus, whatever reference material you would like to or might be able to supply, e.g. photos, sketches or just a rough idea, our expert team of graphic designers will help turn this idea into the perfect design. Working closely with all our customers at every stage of this process, the design will undergo continuous improvements until it meets your vision and a final design can be approved. Based on this final design, the tools will be produced by our in-house specialists.

3. Tool making

Once your concept has been finalized the stamp dies to strike your custom medal / coin are rendered, using different methods / procedures, e.g.:

- Manual engraving, using stock dies

- CNC machine engraving, carving out your custom design

- Hand-designed plaster sculpts and subsequent CNC engraving

4. Coin blanks

Before the actual minting process can begin, blanks are produced using a ‘blanking’ press, punching coin-shaped pieces out of strips of different metal that are transferred to a punch and die set and pressed into shape in a completely self-contained process. State-of-the-art Spalek coin blank finishing systems for pickling and burnishing help smooth any surface blemish to guarantee the hightest quality.

4. Coin blanks

Before the actual minting process can begin, blanks are produced using a ‘blanking’ press, punching coin-shaped pieces out of strips of different metal that are transferred to a punch and die set and pressed into shape in a completely self-contained process. State-of-the-art Spalek coin blank finishing systems for pickling and burnishing help smooth any surface blemish to guarantee the hightest quality.

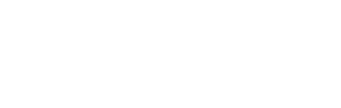

5. Production

This is where the actual coinage takes place, where a blank meets the stamp and is turned into a coin/ medal. With a number of machines available in-house, we are able to use a variety of production methods / techniques to satisfy our customers’ needs. These include:

Striking / minting / embossing, blanking, cold heading, welding, soldering, sawing, enamelling, engraving as well as the use of laser technology.

6. Finishing

To further enhance the functionality or design of these small works of art, finishing touches can be added whenever needed in several consecutive final steps to achieve the desired results.

Techniques applied include enamelling, galvanization, varnishing/ coating.

6. Finishing

To further enhance the functionality or design of these small works of art, finishing touches can be added whenever needed in several consecutive final steps to achieve the desired results.

Techniques applied include enamelling, galvanization, varnishing/ coating.

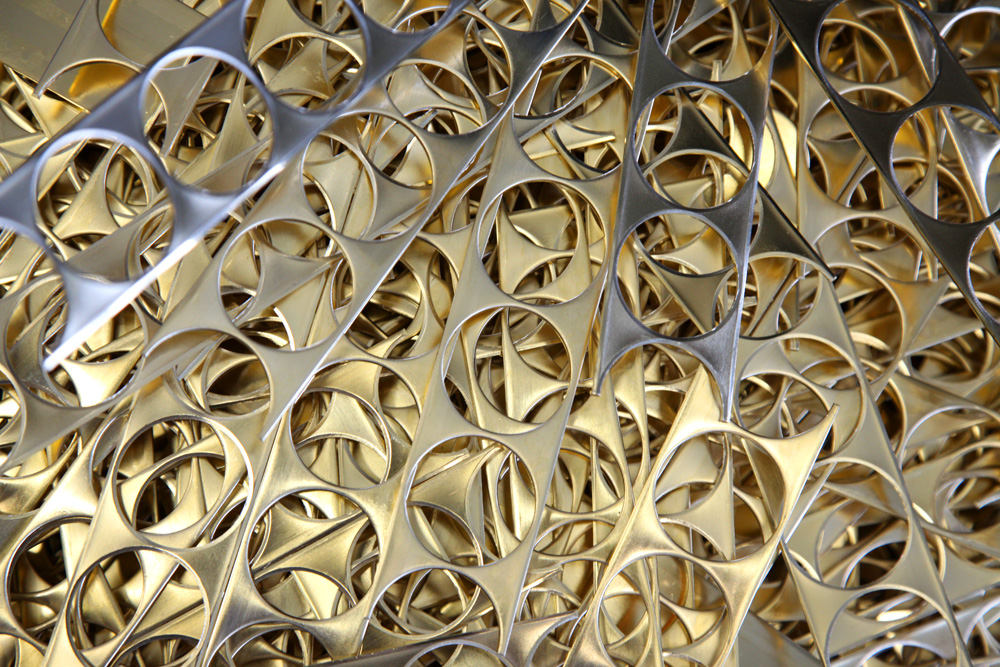

7. Quality Check

Before being shipped, all finished products undergo additional thorough quality checks carried out by our highly skilled staff members, spotting even the slightest flaw or blemish so as to be able to ensure the highest standards in quality and product design.